So in addition to the mirror replacement, I decided to focus on some on aesthetic issues - both very minor and easy to do but the execution would take some time, so I was waiting for a day off like last Monday. Actually, the nature of these tasks meant that I started and ended the day on one of these tasks, with the mirror project done in between!

What task is this? Well if you have a Series 3 (kohki) version R33 GT-R you know how the dashboard surround - yes the black plastic with that slightly rough feeling - scratches very easily and it also picks up dirt easily too! And given that, despite what you might believe otherwise, I actually do drive my car around a bit...

So once again, I took off the panels, starting with the driver's side door window switch assembly, the ashtray, the shift surround, and the main surround.

Then cleared some space on my workbench to take a look at what I needed to do.

So here is one issue:

|

| Look closely - there are also markings on the right corner too |

|

| Using a towel to make sure not to further scratch |

It also means removing the leather shift boot from the shifter surround.

Once all the switches were removed, and I taped up the cigarette lighter surround (I tried to remove but gave up) I did an IPA wipedown of all the parts using a clean, brand new microfiber cloth.

So the technique I use is to use flat black spray paint, but I purposely hold the can further away from a normal painting stance. That allows the paint particles to dry slightly in mid-spray, which results in semi-dry particles landing on the surface. If you recall the plastic itself started out with a slight rough, sandpaper feeling surface, so several passes of this painting technique were required to build up the particles on the surface. So yes this took several hours, but again during this time I worked on replacing the mirror as I described in my previous post.

While I had the surrounds off, I tackled another issue that had been slightly bothering me. Can you tell?

Found that the bulbs WERE LEDs. I can't remember when I did the install, maybe it was something that Worx did?

In any case, it was easy to replace these with the new LEDs. Looks way brighter and cleaner, right?

Meanwhile several coats of flat black spray paint had dried and after confirming the pieces looked great, I started to reassemble. Note that I forgot to take a photo before I reattached the switches to the main surround, I was getting pretty tired at this point.

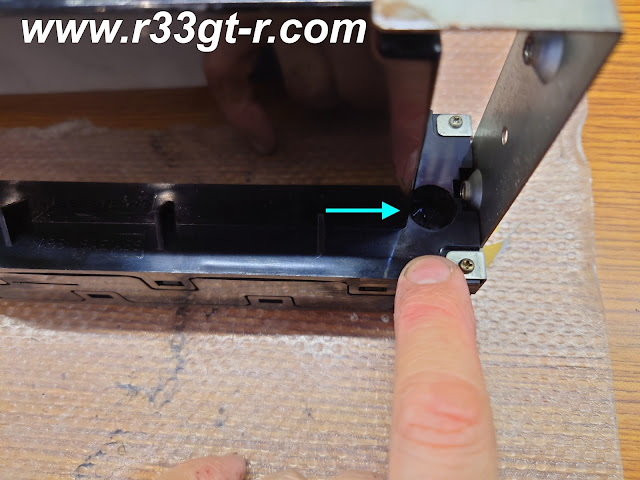

Before reassembling the driver's door switch surround, however, I noticed something.

|

| And this is the THIRD one I used... |

I reassembled the switch into the surround, very carefully to avoid any last minute scratching.